Industrial Ethernet switches provide the structural foundation for modern industrial communication networks. Industrial Ethernet switches allow for reliable real-time communication among controllers, sensors and supervisory systems across tough environments. Industrial Ethernet switches different from commercial switches because designed to operate reliably in harsh environments while delivering deterministic and reliable network performance.

To build a reliable and scalable network, it is critical to understand the architecture, ports, and connectivity options used by the industrial Ethernet switch.

Industrial Ethernet Switch Architecture:

The architecture of an industrial Ethernet switch is developed for consistency in operation, low latency rate, and very high reliability in performance. The basic operation of an industrial Ethernet switch includes the forwarding of Ethernet frames based on MAC addresses and IP addresses with minimum packet loss as a Layer 2 or Layer 3 network.

Key Architectural Elements;

- Switching Fabric: Core component of the industrial Ethernet switch used for high-speed data forwarding rate with minimal latency.

- Control Processor: This manages the operation of the network using network protocols.

- Memory (RAM & Flash): it used to store firmware, routing tables and network configurations.

- Power Management Unit: This section supports a huge voltage input and provide redundancy.

- Industrial Enclosure: Designed as per the industrial environments with immunity to Soak, Dust, Vibration, Surge and EMI.

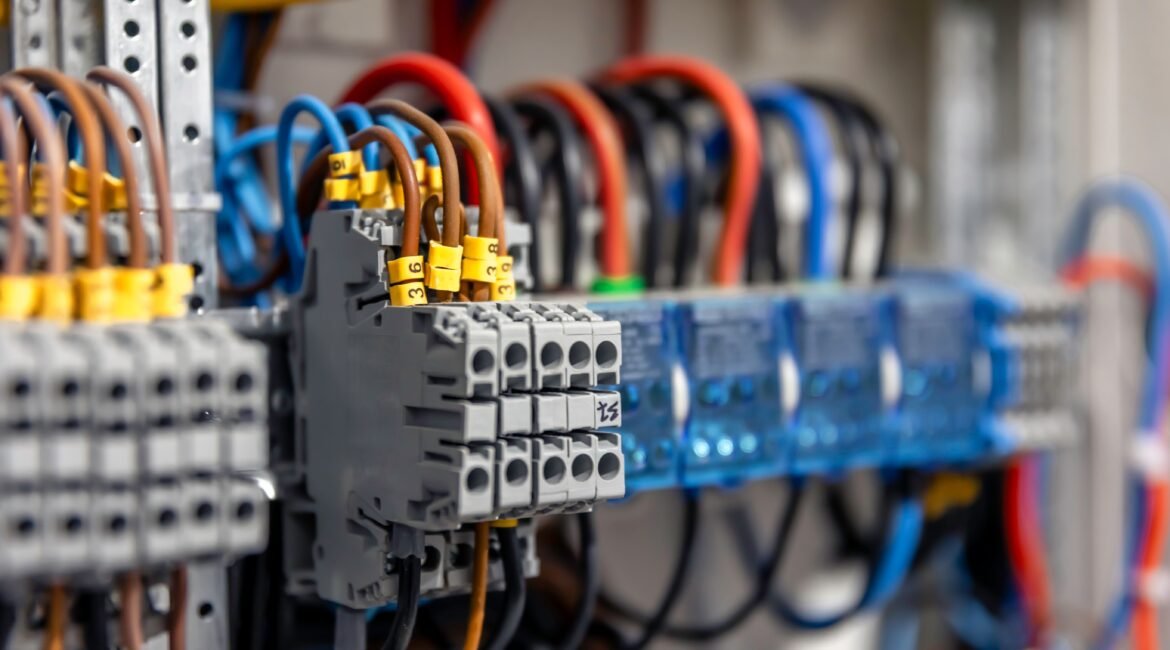

Types of Ports Used by Industrial Ethernet Switch:

The Industrial grade Ethernet switches maximize the use of different port types for communication within different distances, speeds, and tough environments. The port type of an industrial Ethernet switch plays a critical role in determining network performance.

Types of Ports;

- Ethernet Ports (RJ45);

These ports are built to support copper-based Ethernet connectivity, the designed port supports 10/100/1000 Mbps connectivity for short to medium-length cables.

- Fiber Optic Ports (SFP);

Fiber optic ports support long communications and ensure protection against electromagnetic interference, which makes them the best option for high-interference environments.

- Combo Ports;

These ports offer functional advantages of having the capability to support Fiber and copper connectivity on the same port for the multi-purpose industrial application.

- Serial Ports;

These ports provide connectivity for setup and access to the network for management purposes.

Industrial Ethernet Switch Connections:

Basically, this connection is used for an industrial network to support reliability, redundancy, and deterministic connectivity.

Industrial switches support different network topologies based on application requirements.

Connection Topologies;

- Star Topology:

This is the connection point of network which gives easy network management.

- Ring Topology:

This type of connection ensures reliable network performance by using MRP, RSTP, or ERPS protocols for network uptime.

- Line chain or Daisy Chain Topology:

This connection is used for machine-level networks, where the devices are connected in sequence.

- Mesh Topology:

This type of connection is used for large networks in applications requiring multiple redundant paths.

Power and Redundancy Connections:

Power reliability is a key aspect of an industrial network. Industrial Ethernet switches provide the advantage of redundant power inputs for network uptime.

Power Connection Features:

- Redundant DC power inputs for network uptime.

- Wide input voltage range.

- Reverse polarity and overload protection.

- Alarm relays for power failure indication.

Network Monitoring and Control Connections:

Industrial managed switches offer comprehensive network monitoring and control functions which ensure network uptime and provide easy network troubleshooting.

Management Interfaces;

- Web-based Graphical User Interface.

- Command Line Interface.

- SNMP network monitoring.

- Remote network management via VPN or other protocols.

Environmental and Mechanical:

Industrial Ethernet switches are engineered to operate reliably in harsh operating environments in addition, their physical construction supports long-term durability and industrial-grade specifications.

- Key Industrial Design Features

- DIN rail or panel mounting

- Operating temperature range

- High levels of EMC and ESD immunity

- Metal construction

Conclusion:

The architecture, port count, and connectivity of an industrial Ethernet switch have a major influence on the reliability and efficiency of industrial communication networks. By choosing the appropriate switch architecture, port count, and network topology, organizations can create robust networks to support industrial automation, IoT, and other critical operations.

Thanking You.!